11/02

1. There is a certain relationship between the yield strength and fatigue limit of yield strength materials. Generally speaking, the higher the yield strength of materials, the higher the fatigue strength. Therefore, in order to advance the fatigue strength of springs, try to advance the yield strength of spring materials, or use materials with high ratio of yield strength to tensile strength. For the same material, the fine grain arrangement has higher yield strength than the coarse grain arrangement.

11/02

In industrial production, we often need to use stainless steel springs, which is also very common in our daily life. Although it is not a eye-catching item, it brings us many conveniences and is also indispensable in the production process of many equipment. During the use of stainless steel springs, oil contamination or dust pollution may be caused. At this time, we need to clean it in time. Today we will introduce you to the cleaning method of stainless steel spring. I hope you have a simple understanding of this

11/02

In the process of use, the spring shall be subject to the corrosion of harmful gases and work under the corrosion fatigue conditions, causing local corrosion damage on the steel wire surface to form stress concentration, and gradually expanding the corrosion fatigue cracks. The oxidation treatment can make the shell pulling hook spring have certain corrosion resistance. After oxidation treatment, the hook spring can form a dense oxide film on the steel wire surface, which can prevent the corrosion of gunpowder gas.

11/11

The stainless steel spring after heat treatment is attached with a layer of dense oxide skin, which is mainly composed of chromium oxide, nickel oxide and iron chromium oxide. To remove this oxide scale, three main processes should be followed: loosening the oxide scale, etching and removing the etching residue on the spring surface.

11/11

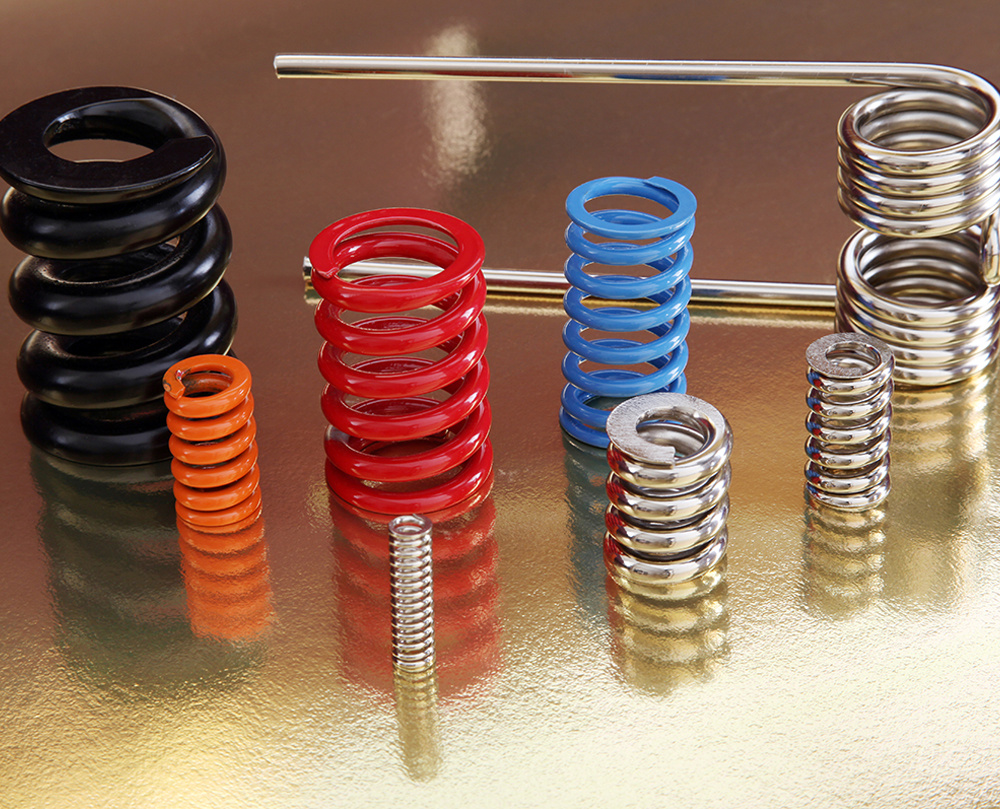

Many customers said that they did not know how to distinguish stainless steel spring from steel wire spring. Of course, customers should be new purchasers, who are not as professional as our spring professionals.

11/11

First, the degree of production intensification is low, and the scale is not up. Take suspension springs as an example, the largest manufacturer only produces more than 1 million pieces each year, and the total output of all the enterprises in China is less than the annual output of Japan's NHK alone. Due to the low degree of intensification, the production capacity of some enterprises is empty, and the other part of enterprises repeat investment, forming a waste of resources.